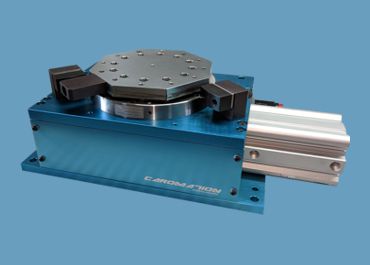

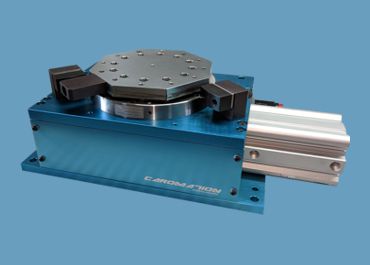

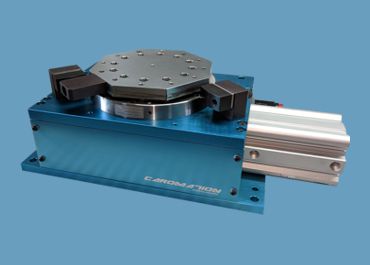

Pneumatic Dial Table

Concern

Most dial tables require a servo setup that includes the motor, drive, and programing. While this setup is idea with multiple positions, when only two positions are needed, it can be quite costly. The customer needed a lower cost system that was both easy to install and set-up.

Opportunity

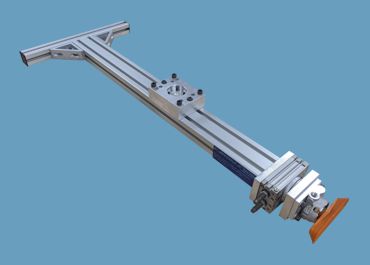

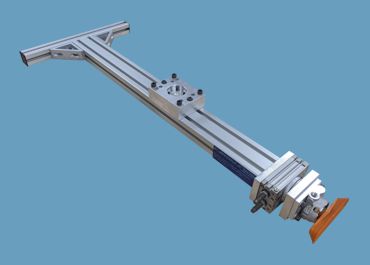

Design a heavy duty, two position, pneumatic dial table with similar performance to a servo system.

Solution

With a main bearing over 10" in diameter, and capable of producing 600 in-pounds of torque, this design fit nicely into the customers application. The two long stroke externally adjustable shocks allow the precise turning once the load is applied. The NAAMS stops are easy to adjust with or without the dial frame. After completion of this special product, the unit was standardized and now available as one of Caromation's standard products.